Platform (Copy)

The Rossini Platform

The developed components are expected to be integrated in to the ROSSINI Platform architecture. The Platform can be represented as an integrated set of layers, each related to a specific dimension/function:

1. Sensing Layer

The Sensing Layer will combine information from safe and non-safe sensors in a fusion module to feed the Safety Aware Control Architecture.

2. Perception Layer

The Perception Layer, through the employment of artificial intelligence techniques, will generate a Semantic Scene Map integrating geometric and semantic information, which will in turn create a set of virtual “Dynamic Shells” for safety, surrounding each object in the scene.

3. Cognitive Layer

The Cognitive Layer will be provided by a high-level scheduler, capable of dynamically planning a set of cooperative actions that the robot needs to execute, and to update them when the working environment conditions, captured by the Semantic Scene Map, change.

4. Control Layer

The Control Layer will interpret the high-level action to execute and will generate the most efficient and safety preserving low-level plan for the robot, thus optimizing trade-off between safety and productivity in the workcell.

5. Actuation Layer

The Actuation Layer will encompass a novel concept of manipulators with built-in safety features, capable of reducing the separation distance between the man and the operator when performing collaborative applications, thus increasing the degree of freedom for robotic applications design.

6. Human Layer

The Human Layer will ensure the inclusion of human-related factors from the early design phases of collaborative applications design, and the constant monitoring of factors influencing job quality during robotic operations.

7. Integration Layer

The Integration Layer will provide integrators with a set of tools and guidelines to ensure inherent safety in design of HRC applications, and to speed up application configuration and reconfiguration.

the Rossini platform

We are testing in real industrial environments

The ROSSINI Platform will be demonstrated into 3 industrial environments up to TRL6. The use cases have been chosen trying to have the widest possible span in terms of application sector, tasks to be executed technologies to be deployed.

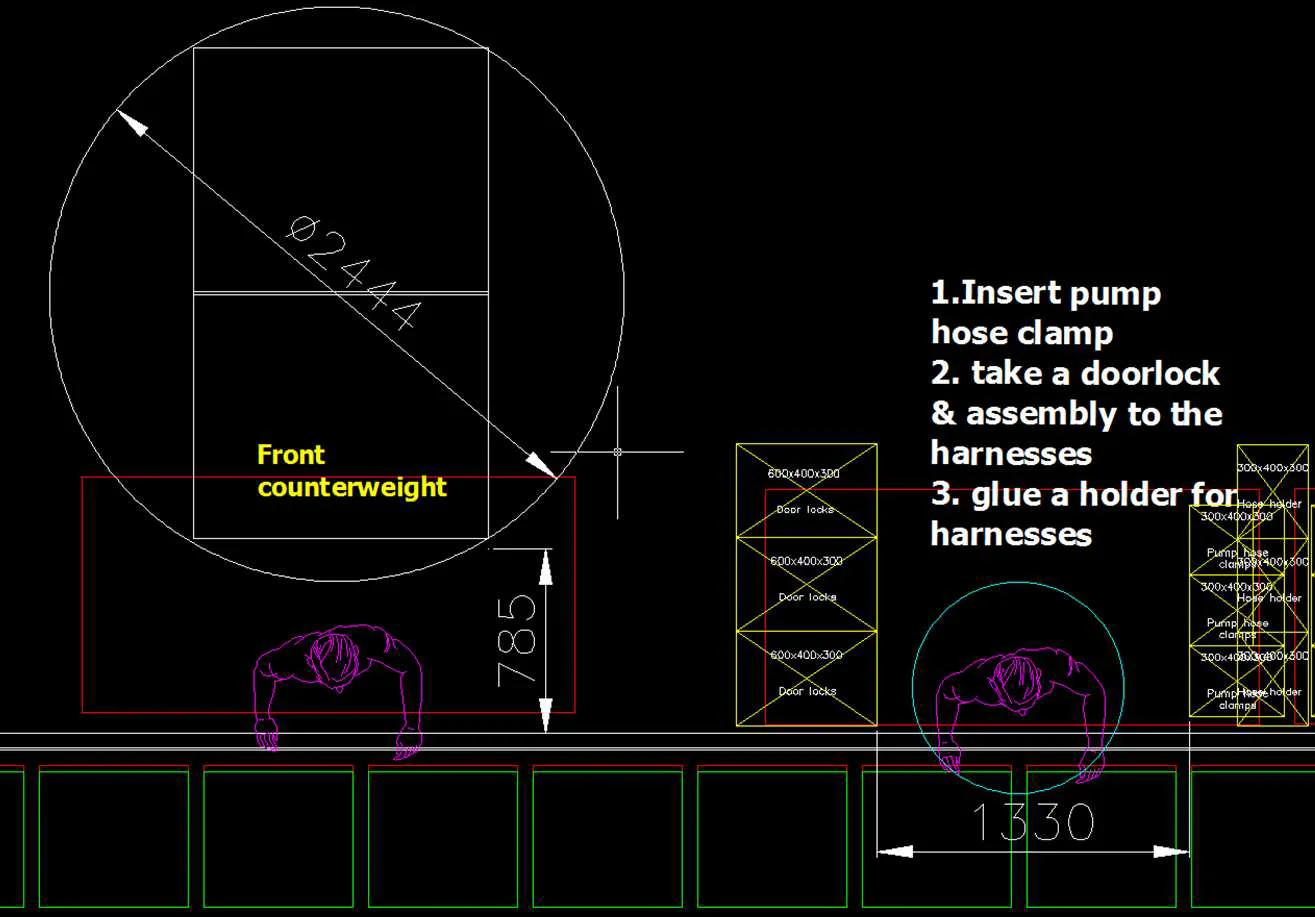

Use Case #1 – Domestic Appliances Assembly (WHIRLPOOL)

In the WHIRLPOOL use case, ROSSINI will deploy the adaptive features of the Human Layer and the Safety Aware Control Architecture in a highly challenging context (continuous flow line) in terms of working speed. The manipulator will be chosen among commercial products, to demonstrate the platform potential to interact with and be wrapped around third party technologies.

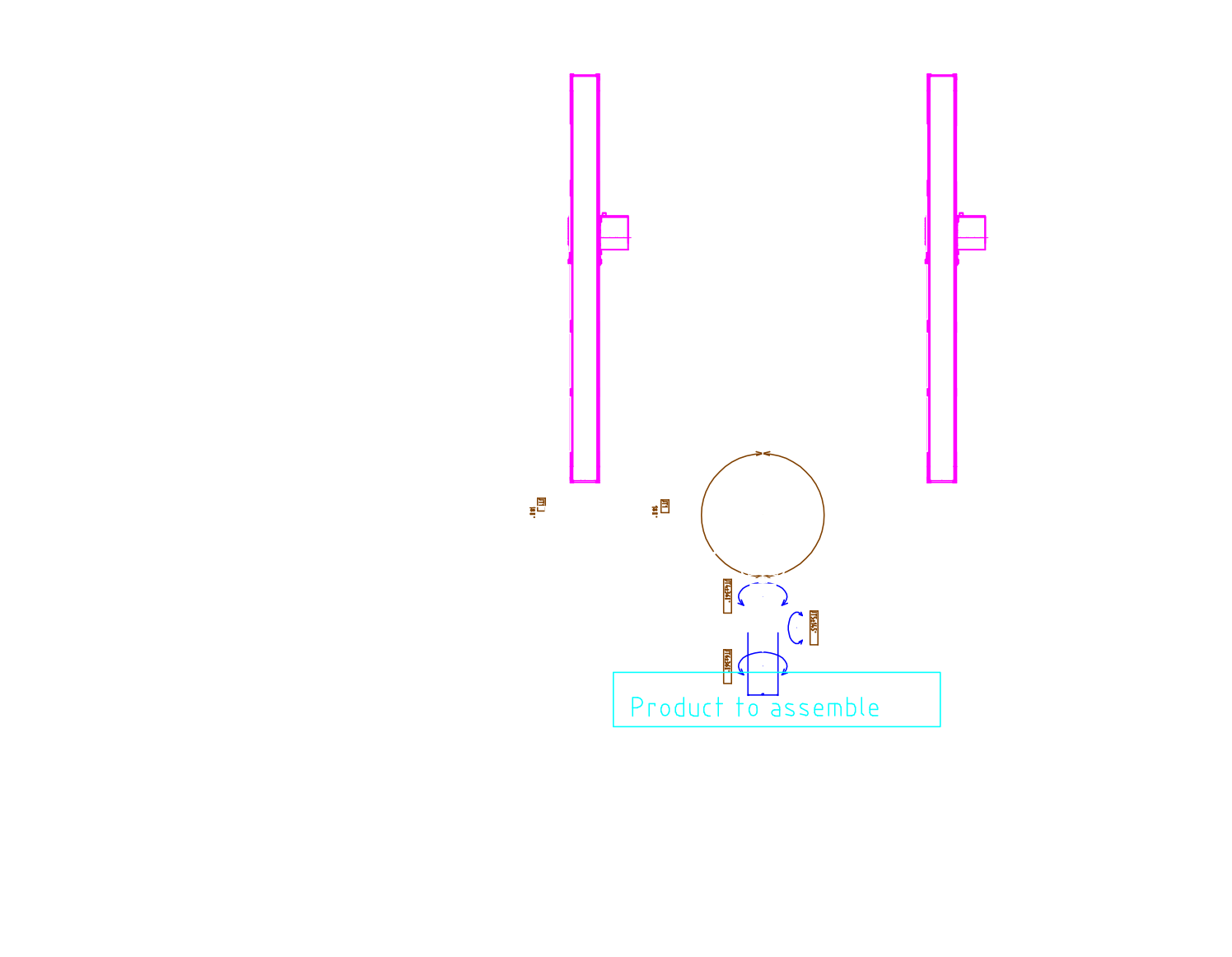

Use Case #2 – Electronic Components Production (SCHINDLER)

In the SCHINDLER use case, ROSSINI will demonstrate the features of the Collaborative by Birth Robotic Manipulator, delivering a low payload robotic arm for electronic components production, integrated with the other platform components (sensing system, controller, etc.). Given the user’s high production variability, the promised ROSSINI performance in terms of production reconfiguration cost savings will be tested.

Use Case #3 – Food Products Packaging (IMA)

In the IMA use case, ROSSINI will deploy a medium payload manipulator mounted on an AGV (mobile robotic platform). The Human Layer and the Control Architecture will be confronted with the challenge to manage navigation operations as well as other operations. Being IMA also a robot integrator, the demonstrator will be easily replicated.